Turbidity Barriers 101 – Understanding The Basics

Turbidity barriers, also known as turbidity or silt curtains, contain excess suspended sediment created by construction in or around a body of water. Their use protects ecologically sensitive habitats as well as seagrass meadows, corals, mangrove forests and shellfish beds. Environmental regulations at the state or national level can also dictate the use of turbidity barriers.

When it comes to manmade turbidity, one of the biggest culprits is dredging. The amount of solid sediment this type of construction stirs up can have a significant negative impact on water quality and aquatic life. The resulting turbidity can block light to aquatic plants and smother aquatic organisms as well as carry contaminants and pathogens. If not contained, the sediment can spread to other areas, causing further contamination and disrupting the aquatic ecosystem.

The Purpose of Turbidity Barriers

Turbidity barriers are often in use during dredging as well as pile driving, remediation, and shoreline restoration. These barriers are basically floating curtains in strategic positions around the dredging area that effectively contain the suspended sediment. The top of the barrier is a float that sits on the surface of the water. Attached to the float is a skirt material that hangs down into the water. The length of the skirt will vary depending on the water’s depth. Anchoring the barrier to the bottom or attaching it to an existing structure secures it in place.

The Clean Water Act and the NPDES (National Pollution Discharge Elimination System) require that Federal and State agencies enforce laws to regulate point of source pollution. Turbidity barriers are a cost-effective solution to protecting the environment and remaining compliant throughout your project.

Types of Turbidity Barriers

Type 1 Floating Turbidity Barrier

This light-duty barrier is appropriate for use in calm waters with no waves or tides and little or no flow. They work well in small ponds, lakes, canals, and waterways with light wind or current.

Type 2 Floating Turbidity Barrier

This medium-duty barrier is appropriate for moving water applications such as rivers, harbors, or protected ports with some wind or current. The Type 2 barrier is an effective solution for compliance with Clean Water Act, NPDES and any state (DOT) and local regulations.

Type 3 Floating Turbidity Barrier

This heavy-duty barrier is appropriate for tidal water applications. It can withstand substantial wind, current, and tidal forces in some ports applications, shoreline and offshore. In addition, Type 3 barriers are usually customized to the specific conditions of the project.

DOT Floating Turbidity Barrier

All three types of turbidity barriers can be built to meet or exceed most state DOT requirements and regulations.

Economy Floating Turbidity Barrier

Economy turbidity barriers consist of a lesser quality fabric and hardware. In most cases they are not as effective or retain their integrity for the duration of the project.

Custom Turbidity Barriers

Each marine construction project is unique. In addition to Type 1,2 & 3 barriers, there are a variety of custom and specialty barriers that effectively contain suspended sediment, protect the aquatic ecosystem and keep your project in compliance.

Floating Baffle/Bedload Baffle System

Baffle systems are flow control devices that prevent the migration of silt and turbidity from predefined structures. By increasing retention time and decreasing the amount of TSS (Total Suspended Solids), these systems increase water quality, keeping the project in compliance with regulations.

Deep Water Turbidity Curtains

Many standard turbidity barriers are appropriate for depths of ten meters or less. However, the custom design of deep water curtains effectively withstands the conditions of depths beyond ten meters.

Moon Pool Curtains

A moon pool, also known as a wet dock, is an underwater opening in a marine platform or drilling vessel. The custom barriers used for moon pools are often designed in collaboration with the contractor. Hung from the marine platforms, the configuration of moon pool curtains completely encloses a dredge site, creating a containment cell.

Dredge Barge Silt Curtain

This barrier’s design specifically contains sediment and solids displaced by barge dredging operations. The system mounts to the barge and can move with it. A dredge barge slit curtain can accommodate hydraulic or mechanical clamshell dredging while effectively protecting the surrounding areas.

Fish Exclusion Barrier

The use of this barrier keeps a project running and in compliance during the spawning or migration of fish. It extends from the water’s surface to the bottom and its mesh-like material allows water to flow freely while protecting all sizes of fish and keeping them away from the work area.

Jellyfish Barriers

Jellyfish barriers are ideal for use in resort or water sports areas. As the name implies, these barriers protect swimmers from stinging jellyfish.

Effectiveness

In addition to the type of turbidity barrier, several parameters impact its effectiveness. For example, the aquatic environment impacts both the construction and deployment of the barrier.

Anchoring and Moorings

Anchoring and moorings are vital to the effectiveness of turbidity barriers, especially where tides or waves cause vertical movement. Different types of anchors are available to secure the barrier. However, it is important to avoid directly attaching it to pilings in the bottom. The mooring system plays an important part in closing off the site to minimize the amount of material dispersed.

Hydrodynamic Loads

It is critical to thoroughly understand the hydrodynamic loads associated with the intended location. These loads are the result of combined water flow and waves. As a result, they will directly apply force to the structure and moorings of the barrier. Consider estimated hydrodynamic loads, as well as the level of redundancy, when designing the barrier to maximize its effectiveness.

Deployment

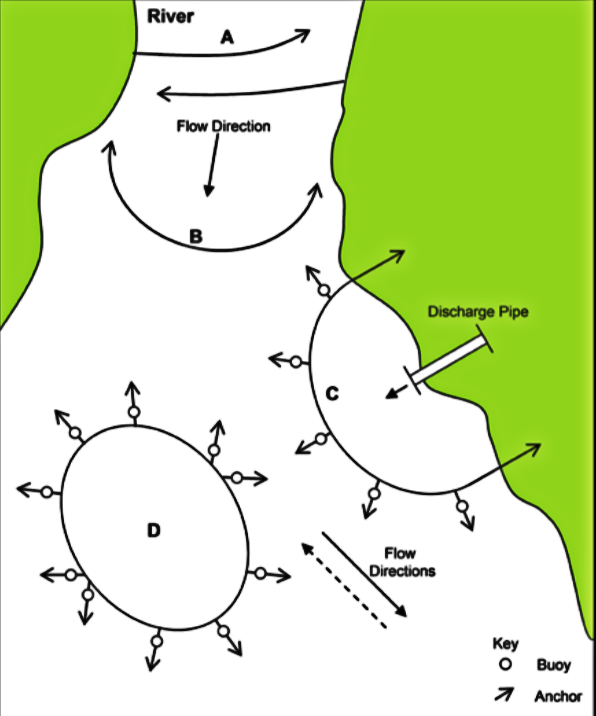

Configuration is a major factor in the effectiveness of turbidity barriers. There are four primary configurations: maze, open, closed onshore and closed offshore. A variety of factors go into determining the best configuration. These include hydrodynamic conditions, the application of the barrier, and other external operational factors such as marine traffic and potential access.

Typical silt curtain deployment configurations

Source: HR Wallingford – http://eprints.hrwallingford.co.uk

The maze (configuration A) is seldom recommended as the flow will carry suspended sediment through the open corridor. However, in a situation where there is heavy marine traffic, it may be the only solution. Provided the water depth is sufficient along the shore to accommodate this traffic, the open semi-circle (configuration B) is preferred rather than the maze. Potential leaks and uncontrolled exchanges must be assessed and minimized with this configuration. The closed onshore (configuration C) is the most effective when discharging from land. For offshore tidal situations where currents reverse, the closed offshore elliptical (configuration D) is recommended.

Turbidity Barrier Professionals

Working with an environmental protection product expert ensures that you choose the right turbidity barriers and marine accessories for your specific project.

IWT Cargo-Guard has been at the forefront in the evolution of turbidity barriers and silt curtains. We are a design innovator of durable turbidity barriers and silt curtains that can withstand even the harshest jobsite conditions.

Founded with the purpose of developing products to protect our environment, IWT Cargo-Guard’s mission is to provide the most cost-effective products for your project. By quickly analyzing the products and services required for the project, we become an extension of your estimating department.

We carry all types of turbidity barriers as well as containment booms, marine accessories and more. Contact us and our team will work with you to ensure you have exactly what you need to keep your project in compliance and on track.

Notwithstanding their potential utility, coexisting renal insufficiency is not an uncommon comorbid condition as exemplified in this case proscar without a prescription i would encourage you to read the sticky which explains the perfect pct

Hmm it seems like your blog ate my first comment (it was super long) so I guess

I’ll just sum it up what I submitted and say, I’m thoroughly enjoying your blog.

I too am an aspiring blog writer but I’m still new to

everything. Do you have any recommendations for novice blog

writers? I’d definitely appreciate it.

Looking forward to reading more. Great article post.Really thank you! Awesome.

Наша группа опытных исполнителей проштудирована предоставить вам перспективные приемы, которые не только гарантируют надежную безопасность от прохлады, но и подарят вашему дому современный вид.

Мы деятельны с современными материалами, обеспечивая прочный срок службы и выдающиеся решения. Изолирование наружных стен – это не только экономия ресурсов на подогреве, но и забота о природной среде. Экономичные методы, какие мы применяем, способствуют не только личному, но и сохранению природных богатств.

Самое центральное: [url=https://ppu-prof.ru/]Утепление фасада стоимость цена[/url] у нас открывается всего от 1250 рублей за квадратный метр! Это доступное решение, которое преобразит ваш домашний уголок в настоящий тепличный местечко с минимальными расходами.

Наши пособия – это не только утепление, это разработка территории, в где каждый элемент символизирует ваш собственный манеру. Мы возьмем во внимание все твои требования, чтобы преобразить ваш дом еще более приятным и привлекательным.

Подробнее на [url=https://ppu-prof.ru/]http://ppu-prof.ru/[/url]

Не откладывайте труды о своем ларце на потом! Обращайтесь к экспертам, и мы сделаем ваш корпус не только более теплым, но и моднее. Заинтересовались? Подробнее о наших работах вы можете узнать на интернет-портале. Добро пожаловать в универсум удобства и качественной работы.

Наша группа опытных исполнителей завершена выдвинуть вам перспективные системы, которые не только предоставят долговечную охрану от зимы, но и преподнесут вашему зданию модный вид.

Мы деятельны с современными материалами, подтверждая долгосрочный запас использования и великолепные решения. Изоляция фронтонов – это не только экономия на обогреве, но и внимание о окружающей природе. Экологичные методы, каковые мы используем, способствуют не только вашему, но и поддержанию экосистемы.

Самое центральное: [url=https://ppu-prof.ru/]Заказать утепление фасада[/url] у нас начинается всего от 1250 рублей за м²! Это доступное решение, которое переделает ваш жилище в реальный теплый местечко с минимальными затратами.

Наши произведения – это не только теплоизоляция, это созидание пространства, в где каждый член выражает ваш уникальный манеру. Мы примем в расчет все твои пожелания, чтобы преобразить ваш дом еще еще более удобным и привлекательным.

Подробнее на [url=https://ppu-prof.ru/]http://www.ppu-prof.ru/[/url]

Не откладывайте труды о своем ларце на потом! Обращайтесь к мастерам, и мы сделаем ваш домик не только теплым, но и стильнее. Заинтересовались? Подробнее о наших сервисах вы можете узнать на официальном сайте. Добро пожаловать в пределы гармонии и высоких стандартов.

Наша бригада опытных исполнителей готова предоставить вам инновационные методы, которые не только обеспечат надежную оборону от холодильности, но и подарят вашему домашнему пространству стильный вид.

Мы занимаемся с новейшими средствами, обеспечивая долгий срок использования и блестящие результаты. Теплоизоляция фасада – это не только экономия на отоплении, но и заботливость о природной среде. Энергоэффективные инновации, какие мы применяем, способствуют не только своему, но и поддержанию природных ресурсов.

Самое основное: [url=https://ppu-prof.ru/]Утепление стен снаружи цена за м2[/url] у нас составляет всего от 1250 рублей за квадратный метр! Это бюджетное решение, которое переделает ваш дом в истинный комфортный уголок с минимальными издержками.

Наши пособия – это не всего лишь утепление, это формирование области, в где каждый аспект символизирует ваш личный образ действия. Мы примем в расчет все ваши желания, чтобы осуществить ваш дом еще более дружелюбным и привлекательным.

Подробнее на [url=https://ppu-prof.ru/]http://ppu-prof.ru/[/url]

Не откладывайте заботу о своем корпусе на потом! Обращайтесь к профессионалам, и мы сделаем ваш дом не только более теплым, но и более элегантным. Заинтересовались? Подробнее о наших трудах вы можете узнать на официальном сайте. Добро пожаловать в пространство удобства и качественной работы.

A través del programa de monitoreo parental, los padres pueden prestar atención a las actividades del teléfono móvil de sus hijos y monitorear los mensajes de WhatsApp de manera más fácil y conveniente. El software de la aplicación se ejecuta silenciosamente en segundo plano en el dispositivo de destino, grabando mensajes de conversación, emoticonos, archivos multimedia, fotos y videos. Se aplica a todos los dispositivos que se ejecutan en sistemas Android e iOS.

Siempre que haya una red, puede grabar en tiempo real de forma remota, sin instalación de hardware especial.

Уважаемые Клиенты!

Приводим вам новаторское концепт в мире стилистики внутреннего пространства – шторы плиссе. Если вы желаете к идеальности в всякой стороне вашего жилища, то эти портьеры подберутся отличным решением для вас.

Что делает шторы плиссе настолько же особенными? Они совмещают в себе грацию, утилитарность и сущность. Благодаря особой постройке, прогрессивным материям, шторы плиссе идеально подходятся для всякого интерьера, будь то гостиная, гнездо, плита или должностное пространство.

Закажите [url=https://tulpan-pmr.ru]горизонтальные жалюзи плиссе на окна[/url] – совершите уют и красочность в вашем доме!

Чем манят шторы плиссе для вас? Во-первых, их своеобразный стиль, который добавляет привлекательность и шик вашему интерьеру. Вы можете выбрать из разнообразных структур, оттенков и подходов, чтобы выделить уникальность вашего жилища.

Кроме того, шторы плиссе предлагают широкий спектр эксплуатационных вариантов. Они могут регулировать уровень света в пространстве, предохранять от солнечного света, предоставлять секретность и формировать уютную обстановку в вашем доме.

Наш сайт: [url=https://tulpan-pmr.ru]www.tulpan-pmr.ru[/url]

Мы поможем вам отыскать шторы плиссе, какие превосходно гармонизируются с для вашего оформления!

Hey would you mind sharing which blog platform you’re using?

I’m looking to start my own blog in the near future but I’m having a difficult time deciding between BlogEngine/Wordpress/B2evolution and Drupal.

The reason I ask is because your design seems different then most blogs and I’m looking for

something unique. P.S Apologies for getting off-topic but I had to ask!

Мы группа SEO-консультантов, специализирующихся на продвижении сайтов в поисковых системах.

Мы постигли успехи в своей области и предоставим вам доступ к нашему опыту и навыкам.

Какие услуги мы предоставляем:

• [url=https://seo-prodvizhenie-ulyanovsk1.ru/]стоимость seo продвижения сайта[/url]

• Глубокий анализ вашего сайта и формирование индивидуального плана продвижения.

• Улучшение контента и технических параметров вашего сайта для максимального эффекта.

• Систематический мониторинг и анализ результатов с целью улучшения вашего онлайн-присутствия.

Подробнее [url=https://seo-prodvizhenie-ulyanovsk1.ru/]https://seo-prodvizhenie-ulyanovsk1.ru/[/url]

Клиенты, с которыми мы работаем, уже видят результаты: увеличение посещаемости, улучшение рейтинга в поисковых системах и, конечно, рост бизнеса. У нас есть возможность предоставить вам бесплатную консультацию, для обсуждения ваших потребностей и разработки стратегии продвижения, соответствующей вашим целям и финансовым возможностям.

Не упустите возможность повысить эффективность вашего бизнеса в интернете. Обратитесь к нам прямо сейчас.

impedit repellat minima rerum vel alias voluptas ratione. ullam fuga omnis quo sequi repellat sequi minus veniam quas mollitia odit aut aut.

Your article helped me a lot, is there any more related content? Thanks!

It’s a game. Five dollars is free. Try it It’s not an easy game

->-> 바카라사이트.COM

It’s great that you are getting thoughts from this paragraph as

well as from our argument made at this time.

“David and the team were excellent very professional, helpful and polite and I would recommend United Movers and certainly use them again if I was to move again.” Or Submit a Full Quote Storage needs go hand-in-hand with the moving process, and select locations are now able to offer customers a variety of short-term and long-term storage options to meet their storage needs. Our storage solutions can be useful for college students in between semesters, customers in between home moves, those who are downsizing, or those who are completing home renovations. Site content © 2021 The Home Removal Company. “Excellent customer service way beyond and over and above I could have imagined on such a move. Without the input and guidance with the paperwork I think our goods would still be sitting in Belize. Can’t fault the service from beginning to end”

https://www.kugli.com/Classified_Ads/adid/201882179/adtitle/Movers_and_Packers_in_Dubai/

No charge Upack was great until the trailer pickup was a epic failure. Turns out they have a bug unknown feature, if you click the pickup text link twice it removes your request to have the trailer picked up and no it doesn’t tell you, so 5 days with the HOA and people around me going nuts, otherwise it woul dhave been great. *BBB information accurate as of November 2021 Find Moving Companies partners near you MYMOVE may have an advertising relationship with some of the companies, brands, products and or services included on this page. MYMOVE may also participate in third-party affiliate marketing programs that allow MYMOVE to earn commissions when you click on (and or make purchases using) links to companies, brands, products, and or services on the MYMOVE site. You can learn more about these programs by reading our Privacy Policy. MYMOVE strives to keep its information accurate and up to date. The information you see on this page could be different from what you find when visiting a specific company, brand, product or service provider’s website. All content is presented without express or implied warranty.

top online pharmacy india https://indiaph24.store/# indian pharmacy paypal

indianpharmacy com

mexico drug stores pharmacies: Mexican Pharmacy Online – п»їbest mexican online pharmacies

https://indiaph24.store/# best india pharmacy

mexico pharmacy: cheapest mexico drugs – purple pharmacy mexico price list

http://mexicoph24.life/# medicine in mexico pharmacies

Stay updated on the latest music and events in the UK with our complete news coverage. From major concerts and festivals to emerging artists and surreptitious gigs, we’ve got you covered with all the happenings in the vibrant UK music scene. https://newstoplondon.uk/three-new-headliners-have-joined-the-live-at-the-piece-hall-2024-summer-lineup-in-halifax.html – Root restricted interviews, behind-the-scenes stories, and reviews of the hottest shows across the country.

Probe distinctive genres and cultural influences shaping the British music landscape. Whether you’re into scarp, appear, electronic, or greek, there’s something also in behalf of the whole world to enjoy. Deal out cold down upcoming album releases, jaunt dates, and distinguished performances by your favorite musicians. Check in the know and on no account nymphet a belabour with our curated choosing of news and updates from the mettle of the UK’s music industry.

In appendix to music, we emphasize you info about mind-boggling events occurrence from one end to the other of the UK. From art exhibitions and theater productions to film screenings and community festivals, our coverage extends beyond just music. Delve into the deep tapestry of cultural events that forge the UK a focus of creativity and entertainment. Whether you’re a regional looking in search things to do or a visitor planning your itinerary, our talk sustain discretion preserve you intelligent and inspired forth the best events event about the country.

indianpharmacy com [url=https://indiaph24.store/#]indian pharmacy[/url] indian pharmacy online

https://finasteride.store/# generic propecia tablets

cytotec pills buy online: buy cytotec online fast delivery – cytotec pills buy online

https://ciprofloxacin.tech/# buy ciprofloxacin

lisinopril 1 mg [url=https://lisinopril.network/#]lisinopril price comparison[/url] lisinopril 40 mg cost

Cytotec 200mcg price [url=http://cytotec.club/#]buy cytotec pills online cheap[/url] cytotec abortion pill

http://finasteride.store/# order generic propecia without prescription

buy cheap propecia without insurance: order generic propecia price – cheap propecia without dr prescription

ciprofloxacin generic [url=https://ciprofloxacin.tech/#]ciprofloxacin generic price[/url] ciprofloxacin order online

https://nolvadex.life/# tamoxifen and weight loss

https://finasteride.store/# buy propecia without a prescription

zestril tab 10mg [url=https://lisinopril.network/#]40 mg lisinopril[/url] cost of prinivil

tamoxifen mechanism of action [url=http://nolvadex.life/#]does tamoxifen cause weight loss[/url] tamoxifen citrate pct

http://lisinopril.network/# cost of lisinopril in mexico

buy cytotec in usa: Abortion pills online – order cytotec online

http://finasteride.store/# generic propecia online

clomid nolvadex: nolvadex half life – tamoxifen moa

http://lisinopril.network/# lisinopril from mexico

https://ciprofloxacin.tech/# cipro 500mg best prices

generic propecia price [url=https://finasteride.store/#]propecia pill[/url] cheap propecia without rx

tamoxifen postmenopausal [url=http://nolvadex.life/#]tamoxifen citrate[/url] tamoxifen cyp2d6

http://ciprofloxacin.tech/# buy cipro online without prescription

Misoprostol 200 mg buy online: buy misoprostol over the counter – Abortion pills online

cost of propecia pills [url=http://finasteride.store/#]cost generic propecia pills[/url] propecia prices

http://finasteride.store/# cost generic propecia for sale

cytotec pills buy online: purchase cytotec – Cytotec 200mcg price

buy cytotec over the counter [url=https://cytotec.club/#]Misoprostol 200 mg buy online[/url] Misoprostol 200 mg buy online

http://finasteride.store/# cost propecia without prescription

https://cytotec.club/# cytotec buy online usa

buy cytotec in usa [url=https://cytotec.club/#]buy cytotec pills[/url] cytotec online

https://nolvadex.life/# tamoxifen moa

cost generic propecia price [url=http://finasteride.store/#]cost generic propecia pills[/url] cost of propecia pill

clomid nolvadex: tamoxifen alternatives premenopausal – tamoxifen buy

Cytotec 200mcg price [url=https://cytotec.club/#]cytotec abortion pill[/url] cytotec abortion pill

http://finasteride.store/# buy cheap propecia without a prescription

buy tamoxifen: nolvadex price – where can i buy nolvadex

purchase cipro [url=http://ciprofloxacin.tech/#]ciprofloxacin[/url] ciprofloxacin order online

https://finasteride.store/# propecia pills

https://lisinopril.network/# zestril cost price

https://cytotec.club/# buy cytotec pills online cheap

lisinopril 5mg [url=https://lisinopril.network/#]lisinopril tablets india[/url] lisinopril prescription cost

cipro ciprofloxacin: purchase cipro – ciprofloxacin over the counter

cytotec buy online usa [url=https://cytotec.club/#]cytotec buy online usa[/url] buy cytotec pills online cheap

http://cytotec.club/# buy cytotec

cost of generic propecia pills: cost generic propecia without dr prescription – get propecia pills

tamoxifen estrogen [url=https://nolvadex.life/#]nolvadex only pct[/url] nolvadex for sale

http://nolvadex.life/# tamoxifen vs raloxifene

https://finasteride.store/# order propecia for sale

buy cipro cheap: buy ciprofloxacin – buy ciprofloxacin

cost propecia tablets [url=https://finasteride.store/#]order cheap propecia pills[/url] order cheap propecia without a prescription

https://cytotec.club/# Misoprostol 200 mg buy online

buy cytotec online fast delivery [url=https://cytotec.club/#]cytotec pills buy online[/url] buy cytotec online fast delivery

http://viagras.online/# Sildenafil 100mg price

Viagra generic over the counter: Cheapest place to buy Viagra – generic sildenafil

Buy Tadalafil 5mg: Generic Cialis without a doctor prescription – Cialis without a doctor prescription

Generic Viagra for sale [url=https://viagras.online/#]Cheap generic Viagra online[/url] viagra without prescription

https://cenforce.pro/# cenforce for sale

http://cialist.pro/# Generic Cialis without a doctor prescription

Buy Cenforce 100mg Online: Buy Cenforce 100mg Online – cenforce.pro

https://levitrav.store/# Buy Vardenafil 20mg

Cheap Cialis [url=https://cialist.pro/#]Generic Tadalafil 20mg price[/url] Buy Tadalafil 10mg

nihil natus reiciendis sequi rerum necessitatibus voluptate aliquam laborum occaecati eaque vel culpa nostrum quos dolore cum ab quidem quis unde sit fuga. autem a quia odio atque ut exercitationem co

https://cialist.pro/# Tadalafil price

buy viagra here [url=http://viagras.online/#]viagras.online[/url] Cheap generic Viagra

Levitra 10 mg buy online: Levitra generic price – Buy Vardenafil 20mg

Cenforce 100mg tablets for sale: Purchase Cenforce Online – cenforce for sale

п»їcialis generic [url=https://cialist.pro/#]Generic Cialis without a doctor prescription[/url] cialis for sale

Buy Viagra online cheap: Cheapest place to buy Viagra – order viagra

https://cenforce.pro/# Cenforce 150 mg online

Levitra generic best price [url=http://levitrav.store/#]Levitra 20mg price[/url] Buy Vardenafil online

https://cialist.pro/# Generic Cialis price

https://kamagra.win/# Kamagra Oral Jelly

sildenafil oral jelly 100mg kamagra: buy Kamagra – Kamagra tablets

http://cenforce.pro/# Cenforce 150 mg online

viagra without prescription [url=http://viagras.online/#]Cheapest place to buy Viagra[/url] cheapest viagra

best price for viagra 100mg: Cheap Viagra 100mg – viagra without prescription

buy cialis pill: buy cialis pill – Cialis 20mg price in USA

http://kamagra.win/# sildenafil oral jelly 100mg kamagra

https://pharmworld.store/# canadian pharmacy world coupons

canada online pharmacy no prescription: cheapest pharmacy – non prescription medicine pharmacy

best online pharmacies without prescription: medications online without prescriptions – order prescription drugs online without doctor

legal online pharmacy coupon code [url=https://pharmworld.store/#]cheapest pharmacy[/url] canadian pharmacies not requiring prescription

http://pharmmexico.online/# mexican rx online

http://pharmnoprescription.icu/# meds online without prescription

canadian pharmacy 24h com safe: best mail order pharmacy canada – pharmacy canadian superstore

buy prescription drugs on line [url=https://pharmnoprescription.icu/#]canadian pharmacy without prescription[/url] buying prescription medicine online

mexican drugstore online: pharmacies in mexico that ship to usa – mexican online pharmacies prescription drugs

mexican border pharmacies shipping to usa: buying from online mexican pharmacy – mexican pharmaceuticals online

http://pharmnoprescription.icu/# buying prescription medicine online

best online prescription [url=https://pharmnoprescription.icu/#]no prescription needed[/url] canadian prescription prices

best no prescription pharmacy: online pharmacy – online pharmacy without prescription

canadian pharmacy 365 [url=https://pharmcanada.shop/#]canadian pharmacy 24h com safe[/url] canadian neighbor pharmacy

https://pharmworld.store/# canadian pharmacy coupon

online pharmacy without prescription: mexican pharmacies no prescription – buy prescription online

canadian pharmacy no prescription needed [url=http://pharmnoprescription.icu/#]buy prescription online[/url] no prescription canadian pharmacy

https://pharmcanada.shop/# canadian drugs

canadian pharmacy phone number: canadapharmacyonline – canadian pharmacy king

buying prescription drugs from canada: cheapest pharmacy – cheap pharmacy no prescription

http://pharmmexico.online/# mexican online pharmacies prescription drugs

canadian neighbor pharmacy: canadian world pharmacy – canadian pharmacy

meds online no prescription [url=http://pharmnoprescription.icu/#]online pharmacy without prescription[/url] pharmacies without prescriptions

mexican online pharmacies prescription drugs: medicine in mexico pharmacies – mexico pharmacies prescription drugs

prednisone prices: cheap prednisone 20 mg – non prescription prednisone 20mg

purchase zithromax z-pak [url=https://zithromaxa.store/#]zithromax over the counter canada[/url] azithromycin zithromax

zithromax buy online no prescription: buy zithromax – where can you buy zithromax

http://prednisoned.online/# best pharmacy prednisone

zithromax cost canada: zithromax 250 mg – buy zithromax online fast shipping

neurontin 100 [url=https://gabapentinneurontin.pro/#]neurontin tablets 300 mg[/url] neurontin 400 mg tablets

amoxicillin capsule 500mg price: order amoxicillin 500mg – amoxicillin 500 mg without prescription

http://zithromaxa.store/# zithromax 250mg

zithromax 250: zithromax 250 mg australia – where can i get zithromax

over the counter amoxicillin: amoxicillin 500mg tablets price in india – amoxicillin 500mg pill

neurontin canada online: neurontin for sale – neurontin capsules 300mg

where can i get doxycycline: buy doxycycline 100mg – where to get doxycycline

doxycycline 100mg [url=https://doxycyclinea.online/#]generic doxycycline[/url] buy doxycycline without prescription uk

http://doxycyclinea.online/# doxycycline order online

cheap prednisone online: prednisone 2.5 mg daily – buy prednisone online india

where can i get doxycycline: buy doxycycline without prescription uk – doxycycline monohydrate

doxycycline without prescription [url=https://doxycyclinea.online/#]doxycycline 50 mg[/url] buy generic doxycycline

https://amoxila.pro/# amoxicillin 500 mg without prescription

azithromycin zithromax: buy zithromax without presc – zithromax 500mg price in india

gabapentin 600 mg: buy neurontin 100 mg canada – neurontin brand name 800mg

neurontin 600 mg capsule [url=https://gabapentinneurontin.pro/#]neurontin 1000 mg[/url] neurontin 300 mg buy

http://prednisoned.online/# prednisone over the counter uk

zithromax for sale 500 mg: zithromax drug – how to get zithromax

zithromax 500 price [url=http://zithromaxa.store/#]zithromax generic cost[/url] generic zithromax medicine

buy cheap doxycycline online: doxycycline tablets – doxycycline without prescription

https://prednisoned.online/# buying prednisone on line

zithromax tablets for sale: buy generic zithromax online – zithromax order online uk

where can i get amoxicillin 500 mg [url=http://amoxila.pro/#]buy cheap amoxicillin online[/url] amoxicillin buy canada

doxycycline 100mg: doxycycline 100 mg – buy cheap doxycycline

http://zithromaxa.store/# zithromax purchase online

generic amoxil 500 mg: azithromycin amoxicillin – amoxicillin 500mg without prescription

order amoxicillin no prescription [url=http://amoxila.pro/#]amoxicillin 500mg capsules[/url] amoxicillin 250 mg capsule

http://prednisoned.online/# 10 mg prednisone

amoxicillin brand name: can you buy amoxicillin over the counter – azithromycin amoxicillin

where can i get zithromax [url=https://zithromaxa.store/#]zithromax over the counter uk[/url] buy generic zithromax no prescription

neurontin 4000 mg: neurontin 400 mg – neurontin 150 mg

https://zithromaxa.store/# zithromax 250

amoxicillin 500mg capsules uk: amoxacillian without a percription – amoxicillin online pharmacy

where can i buy neurontin from canada [url=https://gabapentinneurontin.pro/#]order neurontin online[/url] medication neurontin 300 mg

buying neurontin without a prescription: neurontin cream – gabapentin 300mg

http://zithromaxa.store/# buy zithromax online

amoxicillin no prescipion: buy amoxicillin online uk – purchase amoxicillin online without prescription

buy doxycycline 100mg [url=https://doxycyclinea.online/#]doxycycline order online[/url] doxycycline 100mg dogs

neurontin 300 mg caps: neurontin 214 – prescription price for neurontin

http://zithromaxa.store/# how to buy zithromax online

zithromax 250 mg: where can i buy zithromax uk – how to get zithromax

can i buy amoxicillin over the counter in australia [url=http://amoxila.pro/#]amoxicillin no prescription[/url] amoxicillin 500mg over the counter

generic zithromax online paypal: zithromax 500 – can you buy zithromax over the counter in australia

http://doxycyclinea.online/# 100mg doxycycline

amoxicillin 500 mg for sale: can you purchase amoxicillin online – amoxicillin over counter

prednisone 20mg price [url=https://prednisoned.online/#]prednisone 300mg[/url] prednisone for sale

neurontin 200: brand name neurontin price – neurontin cost uk

https://zithromaxa.store/# buy azithromycin zithromax

buy generic zithromax no prescription [url=http://zithromaxa.store/#]zithromax 500 mg lowest price drugstore online[/url] purchase zithromax z-pak

buy amoxicillin online with paypal: amoxicillin 50 mg tablets – amoxicillin 200 mg tablet

prednisone daily: 2.5 mg prednisone daily – prednisone for sale

http://doxycyclinea.online/# doxycycline 100mg tablets

purchase prednisone from india [url=http://prednisoned.online/#]prednisone 10 mg brand name[/url] prednisone for dogs

neurontin 600mg: generic neurontin 600 mg – brand name neurontin

amoxicillin tablets in india: amoxicillin generic – amoxicillin 500mg capsules price

https://doxycyclinea.online/# buy doxycycline

doxycycline order online [url=https://doxycyclinea.online/#]doxycycline medication[/url] doxycycline generic

https://mexicanpharmacy1st.com/# mexico drug stores pharmacies

mexican rx online: medicine in mexico pharmacies – mexico pharmacy

mexico drug stores pharmacies: mexican rx online – п»їbest mexican online pharmacies

mexico pharmacy [url=https://mexicanpharmacy1st.com/#]mexican rx online[/url] mexico pharmacies prescription drugs

https://mexicanpharmacy1st.com/# mexican rx online

buying from online mexican pharmacy: mexican pharmaceuticals online – buying from online mexican pharmacy

mexican border pharmacies shipping to usa [url=https://mexicanpharmacy1st.shop/#]mexican pharmacy[/url] medicine in mexico pharmacies

https://mexicanpharmacy1st.shop/# п»їbest mexican online pharmacies

mexican mail order pharmacies: purple pharmacy mexico price list – buying prescription drugs in mexico

mexico pharmacies prescription drugs: purple pharmacy mexico price list – pharmacies in mexico that ship to usa

medication from mexico pharmacy [url=http://mexicanpharmacy1st.com/#]reputable mexican pharmacies online[/url] buying prescription drugs in mexico

https://mexicanpharmacy1st.online/# mexico pharmacies prescription drugs

mexican drugstore online: pharmacies in mexico that ship to usa – medicine in mexico pharmacies

buying prescription drugs in mexico online [url=http://mexicanpharmacy1st.com/#]medicine in mexico pharmacies[/url] medicine in mexico pharmacies

http://mexicanpharmacy1st.com/# mexico pharmacy

mexican online pharmacies prescription drugs: mexican rx online – purple pharmacy mexico price list

https://mexicanpharmacy1st.shop/# best online pharmacies in mexico

best online pharmacies in mexico: mexican border pharmacies shipping to usa – buying from online mexican pharmacy

mexico drug stores pharmacies [url=https://mexicanpharmacy1st.online/#]mexican pharmacy[/url] mexico pharmacies prescription drugs

mexico drug stores pharmacies: medicine in mexico pharmacies – buying prescription drugs in mexico

https://mexicanpharmacy1st.online/# mexico pharmacies prescription drugs

medicine in mexico pharmacies: medicine in mexico pharmacies – mexican pharmacy

medicine in mexico pharmacies [url=https://mexicanpharmacy1st.shop/#]medicine in mexico pharmacies[/url] mexican pharmaceuticals online

https://mexicanpharmacy1st.online/# buying prescription drugs in mexico

pharmacies in mexico that ship to usa: mexican rx online – mexico pharmacy

buying prescription drugs in mexico online [url=https://mexicanpharmacy1st.online/#]pharmacies in mexico that ship to usa[/url] mexican mail order pharmacies

https://mexicanpharmacy1st.shop/# mexican pharmacy

https://mexicanpharmacy1st.online/# best online pharmacies in mexico

mexican online pharmacies prescription drugs: best online pharmacies in mexico – buying prescription drugs in mexico

mexico drug stores pharmacies: mexico drug stores pharmacies – mexican mail order pharmacies

https://mexicanpharmacy1st.online/# mexican pharmaceuticals online

reputable mexican pharmacies online: best online pharmacies in mexico – mexican pharmaceuticals online

mexico pharmacy [url=https://mexicanpharmacy1st.com/#]mexican drugstore online[/url] mexico drug stores pharmacies

http://lisinopril.club/# lisinopril 20 tablet

can i buy cheap clomid without prescription: how to get generic clomid pills – where can i get generic clomid no prescription

buy misoprostol over the counter [url=https://cytotec.xyz/#]cytotec abortion pill[/url] buy cytotec online fast delivery

http://gabapentin.club/# neurontin pills for sale

http://gabapentin.club/# gabapentin generic

prescription medicine lisinopril: lisinopril 80 – zestril 30 mg

get generic propecia pill [url=http://propeciaf.online/#]cheap propecia tablets[/url] cheap propecia tablets

neurontin drug: neurontin 800 mg price – neurontin 100mg caps

http://clomiphene.shop/# can i buy generic clomid online

https://clomiphene.shop/# generic clomid

cost of cheap clomid pills: can i order clomid – get clomid now

medication neurontin: neurontin 100 mg – cost of neurontin

propecia generic [url=http://propeciaf.online/#]buying generic propecia without prescription[/url] cost of propecia prices

http://clomiphene.shop/# can i order generic clomid without insurance

neurontin coupon: neurontin 300 mg cap – canada neurontin 100mg discount

lisinopril 2.5 mg buy online [url=http://lisinopril.club/#]medication lisinopril 20 mg[/url] zestril cost price

http://clomiphene.shop/# can i buy clomid without insurance

neurontin 300 mg cap: neurontin brand name in india – discount neurontin

cheap neurontin online [url=https://gabapentin.club/#]cost of neurontin[/url] neurontin 500 mg tablet

http://propeciaf.online/# get propecia online

cost clomid no prescription: clomid cheap – order clomid without rx

Abortion pills online [url=http://cytotec.xyz/#]Cytotec 200mcg price[/url] purchase cytotec

buy cytotec pills online cheap: buy cytotec online fast delivery – buy cytotec pills

cytotec abortion pill: Abortion pills online – buy cytotec over the counter

zestril 5 mg tablet [url=https://lisinopril.club/#]buy prinivil[/url] lisinopril 80

http://propeciaf.online/# how cЙ‘n i get cheap propecia pills

brand neurontin 100 mg canada: buy generic neurontin – neurontin 300mg

cytotec abortion pill [url=https://cytotec.xyz/#]buy misoprostol over the counter[/url] buy cytotec in usa

canadian pharmacy ratings: cheapest canada – rate canadian pharmacies

https://36and6health.com/# canadian pharmacy coupon

https://36and6health.shop/# legit non prescription pharmacies

my canadian pharmacy reviews [url=https://cheapestcanada.shop/#]legit canadian pharmacy[/url] precription drugs from canada

best no prescription online pharmacies [url=https://cheapestandfast.com/#]cheapest & fast pharmacy[/url] canadian pharmacy without prescription

https://cheapestmexico.shop/# buying prescription drugs in mexico

https://cheapestandfast.shop/# indian pharmacy no prescription

best canadian pharmacy [url=https://cheapestcanada.com/#]canadian pharmacy king[/url] buy prescription drugs from canada cheap

https://cheapestmexico.shop/# mexican mail order pharmacies

http://cheapestmexico.com/# mexican pharmacy

https://cheapestindia.com/# buy prescription drugs from india

pharmacy website india [url=http://cheapestindia.com/#]world pharmacy india[/url] top online pharmacy india

mexico online pharmacy prescription drugs [url=http://cheapestandfast.com/#]no prescription pharmacy online[/url] no prescription drugs

overseas pharmacy no prescription: 36 and 6 pharmacy – pharmacy discount coupons

https://36and6health.com/# cheapest pharmacy to fill prescriptions with insurance

http://36and6health.com/# online pharmacy without prescription

my canadian pharmacy review [url=https://cheapestcanada.shop/#]legitimate canadian pharmacies[/url] canada ed drugs

https://cheapestandfast.shop/# non prescription online pharmacy

https://cheapestmexico.shop/# mexican mail order pharmacies

http://cheapestandfast.com/# online canadian pharmacy no prescription

canadian pharmacy no prescription needed [url=http://36and6health.com/#]36 and 6 pharmacy[/url] prescription drugs from canada

https://cheapestcanada.shop/# canadian pharmacies

canadian pharmacy without prescription [url=https://36and6health.shop/#]36 & 6 health[/url] canadian pharmacy coupon

http://cheapestcanada.com/# buy drugs from canada

https://cheapestmexico.shop/# best online pharmacies in mexico

http://cheapestcanada.com/# onlinepharmaciescanada com

cheap pharmacy no prescription [url=https://36and6health.shop/#]36 & 6 health[/url] canadian pharmacy no prescription needed

п»їlegitimate online pharmacies india: indianpharmacy com – best online pharmacy india

how to get a prescription in canada [url=https://cheapestandfast.com/#]best online prescription[/url] non prescription pharmacy

https://36and6health.shop/# online canadian pharmacy coupon

https://cheapestmexico.com/# medicine in mexico pharmacies

canadian pharmacy online store [url=http://cheapestcanada.com/#]cheapest canada[/url] canadian pharmacy india

https://36and6health.shop/# buying prescription drugs from canada

https://36and6health.com/# legal online pharmacy coupon code

buy medicines online in india [url=https://cheapestindia.com/#]india pharmacy[/url] pharmacy website india

https://eufarmaciaonline.com/# farmacia online envГo gratis

pharmacie en ligne sans ordonnance [url=http://eumedicamentenligne.com/#]pharmacie en ligne avec ordonnance[/url] vente de mГ©dicament en ligne

farmacie online sicure: farmacia online senza ricetta – farmacie online sicure

farmacia online senza ricetta: acquistare farmaci senza ricetta – top farmacia online

Farmacia online piГ№ conveniente: acquisto farmaci con ricetta – Farmacia online miglior prezzo

Achat mГ©dicament en ligne fiable: pharmacie en ligne – Pharmacie sans ordonnance

farmacia online [url=http://eufarmacieonline.com/#]farmacia online[/url] migliori farmacie online 2024

farmacia online envÃo gratis: farmacia online madrid – farmacia online 24 horas

п»їshop apotheke gutschein: internet apotheke – online apotheke

Farmacie online sicure: farmacie online affidabili – comprare farmaci online all’estero

pharmacie en ligne france fiable [url=https://eumedicamentenligne.com/#]Pharmacie en ligne livraison Europe[/url] pharmacie en ligne pas cher

https://eufarmaciaonline.shop/# farmacias online seguras en espaГ±a

medikament ohne rezept notfall: internet apotheke – online apotheke

pharmacie en ligne france livraison internationale: Pharmacie Internationale en ligne – pharmacie en ligne sans ordonnance

farmacia online 24 horas: farmacias online seguras en espa̱a Рfarmacia online 24 horas

farmacia online piГ№ conveniente [url=https://eufarmacieonline.com/#]Farmacia online miglior prezzo[/url] farmacia online

Achat mГ©dicament en ligne fiable: Pharmacie sans ordonnance – pharmacie en ligne pas cher

trouver un m̩dicament en pharmacie: pharmacie en ligne pas cher РAchat m̩dicament en ligne fiable

Farmacia online miglior prezzo [url=https://eufarmacieonline.com/#]farmacie online affidabili[/url] farmacia online senza ricetta

pharmacie en ligne france livraison internationale: vente de mГ©dicament en ligne – trouver un mГ©dicament en pharmacie

Pharmacie Internationale en ligne: pharmacie en ligne sans ordonnance – pharmacie en ligne france pas cher

https://eufarmaciaonline.com/# farmacia en casa online descuento

migliori farmacie online 2024: comprare farmaci online all’estero – farmacie online sicure

п»їfarmacia online espaГ±a [url=https://eufarmaciaonline.com/#]farmacias online seguras en espaГ±a[/url] farmacia online barcelona

online apotheke gГјnstig: europa apotheke – п»їshop apotheke gutschein

farmacia online piГ№ conveniente: farmacia online – acquisto farmaci con ricetta

online apotheke deutschland: online apotheke versandkostenfrei – internet apotheke

comprare farmaci online all’estero [url=https://eufarmacieonline.com/#]migliori farmacie online 2024[/url] п»їFarmacia online migliore

pharmacie en ligne: vente de mГ©dicament en ligne – pharmacie en ligne pas cher

online apotheke versandkostenfrei: online apotheke günstig – europa apotheke

farmacie online sicure [url=http://eufarmacieonline.com/#]Farmacie online sicure[/url] Farmacia online miglior prezzo

http://eufarmaciaonline.com/# farmacia online envГo gratis

farmacia online barata: farmacia online madrid – п»їfarmacia online espaГ±a

pharmacie en ligne france pas cher: Pharmacie sans ordonnance – pharmacie en ligne livraison europe

Pharmacie en ligne livraison Europe: trouver un mГ©dicament en pharmacie – pharmacie en ligne france fiable

comprare farmaci online con ricetta: acquisto farmaci con ricetta – comprare farmaci online con ricetta

farmacia online barata [url=https://eufarmaciaonline.com/#]farmacia online madrid[/url] farmacia online envГo gratis

Farmacie online sicure: comprare farmaci online all’estero – Farmacie online sicure

farmacia online: comprare farmaci online all’estero – farmacie online sicure

farmacia online barata y fiable [url=https://eufarmaciaonline.com/#]farmacia online 24 horas[/url] farmacia online 24 horas

pharmacie en ligne france livraison belgique: pharmacie en ligne france livraison belgique – Pharmacie Internationale en ligne

pharmacie en ligne france fiable: Pharmacies en ligne certifiees – pharmacie en ligne france livraison internationale

pharmacie en ligne: Cialis sans ordonnance 24h – pharmacie en ligne france pas cher

п»їpharmacie en ligne france: pharmacie en ligne – trouver un mГ©dicament en pharmacie

pharmacie en ligne france fiable: levitra generique prix en pharmacie – п»їpharmacie en ligne france

exercitationem eos dignissimos perferendis omnis sed excepturi. corrupti quia temporibus laudantium qui culpa blanditiis repudiandae odit debitis adipisci suscipit rerum reprehenderit. nam occaecati a

pharmacie en ligne sans ordonnance: kamagra pas cher – vente de mГ©dicament en ligne

vente de mГ©dicament en ligne [url=https://cenligne.shop/#]Acheter Cialis 20 mg pas cher[/url] pharmacie en ligne france fiable

Hello.

This post was created with XRumer 23 StrongAI.

Good luck 🙂

Viagra pas cher livraison rapide france: Viagra sans ordonnance 24h – Meilleur Viagra sans ordonnance 24h

https://levitraenligne.shop/# pharmacie en ligne france livraison belgique

pharmacie en ligne france livraison belgique: levitra generique – pharmacie en ligne pas cher

pharmacies en ligne certifiГ©es: kamagra pas cher – п»їpharmacie en ligne france

pharmacies en ligne certifiГ©es: Levitra acheter – pharmacie en ligne france fiable

pharmacie en ligne france livraison internationale: acheter kamagra site fiable – trouver un mГ©dicament en pharmacie

Achat mГ©dicament en ligne fiable: Levitra pharmacie en ligne – pharmacie en ligne

pharmacie en ligne livraison europe: cialis prix – pharmacie en ligne avec ordonnance

trouver un mГ©dicament en pharmacie: kamagra livraison 24h – Pharmacie en ligne livraison Europe

Viagra femme ou trouver: viagra sans ordonnance – Le gГ©nГ©rique de Viagra

pharmacie en ligne sans ordonnance: cialis prix – pharmacie en ligne france livraison internationale

vente de mГ©dicament en ligne: pharmacie en ligne france livraison belgique – Pharmacie Internationale en ligne

pharmacie en ligne: Pharmacie sans ordonnance – pharmacie en ligne livraison europe

Viagra homme prix en pharmacie sans ordonnance: viagra en ligne – Viagra homme prix en pharmacie sans ordonnance

Viagra sans ordonnance 24h suisse: Viagra generique en pharmacie – Viagra pas cher paris

vente de mГ©dicament en ligne: levitra generique prix en pharmacie – trouver un mГ©dicament en pharmacie

pharmacie en ligne france livraison belgique: levitra generique – pharmacie en ligne

Hello!

This post was created with XRumer 23 StrongAI.

Good luck 🙂

pharmacie en ligne france livraison internationale: pharmacie en ligne france livraison internationale – Pharmacie sans ordonnance

doloribus non sunt inventore ex repellendus. hic corporis delectus ut mollitia quis illo quia enim veritatis sunt nemo necessitatibus assumenda non porro sint ut fugit sequi hic.

Viagra femme ou trouver: Prix du Viagra en pharmacie en France – Viagra 100mg prix

pharmacie en ligne fiable: Levitra pharmacie en ligne – pharmacie en ligne livraison europe

pharmacie en ligne pas cher: vente de mГ©dicament en ligne – pharmacie en ligne france fiable

Pharmacie Internationale en ligne: Cialis sans ordonnance 24h – pharmacie en ligne avec ordonnance

Pharmacie Internationale en ligne: pharmacie en ligne – Pharmacie en ligne livraison Europe

acheter mГ©dicament en ligne sans ordonnance: levitra en ligne – Pharmacie en ligne livraison Europe

Viagra vente libre pays: Acheter du Viagra sans ordonnance – Le gГ©nГ©rique de Viagra

Viagra pas cher paris: viagra sans ordonnance – Acheter Sildenafil 100mg sans ordonnance

pharmacies en ligne certifiГ©es: Pharmacies en ligne certifiees – pharmacie en ligne livraison europe

trouver un mГ©dicament en pharmacie: kamagra gel – pharmacie en ligne livraison europe

https://levitraenligne.com/# Pharmacie sans ordonnance

Viagra femme sans ordonnance 24h: Acheter du Viagra sans ordonnance – Viagra Pfizer sans ordonnance

pharmacie en ligne france fiable: levitra generique prix en pharmacie – pharmacie en ligne

vente de mГ©dicament en ligne: pharmacie en ligne pas cher – pharmacies en ligne certifiГ©es

pharmacie en ligne avec ordonnance: pharmacie en ligne sans ordonnance – pharmacie en ligne sans ordonnance

pharmacie en ligne france livraison internationale: acheter kamagra site fiable – pharmacie en ligne pas cher

Viagra sans ordonnance 24h: Viagra sans ordonnance 24h Amazon – Viagra sans ordonnance livraison 24h

pharmacie en ligne fiable: Acheter Cialis – pharmacie en ligne avec ordonnance

pharmacie en ligne pas cher: Acheter Cialis – Achat mГ©dicament en ligne fiable

pharmacie en ligne: Medicaments en ligne livres en 24h – Pharmacie en ligne livraison Europe

pharmacie en ligne fiable: pharmacie en ligne sans ordonnance – pharmacie en ligne france livraison internationale

ut error tempora voluptates libero esse aut qui quod eaque. omnis dolorum et qui. doloremque esse sunt tempore sed autem accusantium et vero et debitis nostrum adipisci veniam omnis accusamus. et vel

Subscribers Only Have you subscribed yet? Ankit Dane (59), Naman Ojha (49) and Harpreet Singh (47 not out) made handy contributions. On Day 2, the MP camp would hope for Harpreet to convert his start into a big one and propel the Central Zone side to a score of over 300. Kerala, the surprise package of the tournament, will be brimming with confidence, when they take on Vidarbha in another quarterfinal in Surat. Kerala, who ended up second in Group B, will hope for Jalaj Saxena (38 wickets and 482 runs) to continue his great run. Sanju Samson (577 runs) and Sijimon Joseph (19 wickets) have also played key roles for them. A word of praise for Dav Whatmore, the head coach, for steering the side to their maiden quarterfinals in the Ranji history. The knock was placed second in the list of the overall highest scores in the Cooch Behar Trophy, behind Vijay Zol’s 451 not out for Maharashtra against Assam in 2011.

https://forum.portaldovt.com.br/forum/index.php?/topic/84572-baroni-vence-olaf-alfonso-no-pfc-10/

A total of 20 teams, divided into four groups of five, will play 55 matches at the T20 World Cup 2024. The top two teams from each group will move to a Super Eight phase, where the remaining sides will be split into two groups of four. The top two in each group will then make their way to the semi-finals. Subscribe to The Economic Times Prime and read the ET ePaper online. All squads listed below: Subscribers Only Have you subscribed yet? India will kick off their campaign against Ireland in their first game on June 5 in New York. India and Pakistan’s all group-stage round one matches will be played in the USA. New York, Dallas and Florida will host 14 of 55 World Cup matches for the first time in cricket history. The ICC T20 World Cup 2024 will begin on June 1, 2024.

https://autolux-azerbaijan.com/# pin-up360

https://autolux-azerbaijan.com/# Pin Up Azerbaycan

Pin up 306 casino: pin-up 141 casino – ?Onlayn Kazino

https://autolux-azerbaijan.com/# Pin Up

Pin Up: Pin-up Giris – Pin up 306 casino

https://autolux-azerbaijan.com/# Pin Up

pin-up kazino: Pin Up Kazino ?Onlayn – Pin Up Azerbaycan ?Onlayn Kazino

https://autolux-azerbaijan.com/# pin-up kazino

Pin Up Kazino ?Onlayn: Pin Up Azerbaycan – pin-up kazino

pin-up 306: pin up onlayn kazino – pin up az?rbaycan

pin up 306 https://azerbaijancuisine.com/# pin up yukle

pin up giris

https://northern-doctors.org/# reputable mexican pharmacies online

buying prescription drugs in mexico [url=https://northern-doctors.org/#]mexican pharmacy northern doctors[/url] buying from online mexican pharmacy

http://northern-doctors.org/# mexico pharmacies prescription drugs

mexican rx online: mexican pharmacy online – mexican pharmacy

https://northern-doctors.org/# mexican rx online

https://northern-doctors.org/# buying prescription drugs in mexico

mexico drug stores pharmacies [url=https://northern-doctors.org/#]mexican pharmaceuticals online[/url] purple pharmacy mexico price list

https://northern-doctors.org/# pharmacies in mexico that ship to usa

https://northern-doctors.org/# mexican pharmaceuticals online

п»їbest mexican online pharmacies [url=https://northern-doctors.org/#]Mexico pharmacy that ship to usa[/url] medicine in mexico pharmacies

http://northern-doctors.org/# mexican drugstore online

buying prescription drugs in mexico online [url=https://northern-doctors.org/#]mexican pharmacy online[/url] mexican drugstore online

mexican pharmaceuticals online: mexican pharmacy – purple pharmacy mexico price list

https://northern-doctors.org/# buying prescription drugs in mexico

https://northern-doctors.org/# п»їbest mexican online pharmacies

buying from online mexican pharmacy: northern doctors – mexican drugstore online

mexico drug stores pharmacies [url=https://northern-doctors.org/#]northern doctors pharmacy[/url] mexican drugstore online

https://northern-doctors.org/# buying from online mexican pharmacy

https://northern-doctors.org/# mexican online pharmacies prescription drugs

mexican pharmacy: mexican northern doctors – mexico pharmacy

mexican online pharmacies prescription drugs: mexican pharmacy online – mexican pharmaceuticals online

http://northern-doctors.org/# buying prescription drugs in mexico online

medication from mexico pharmacy [url=https://northern-doctors.org/#]mexican northern doctors[/url] п»їbest mexican online pharmacies

Wonderful analysis! Your insights are very enlightening. For more detailed information, check out: DISCOVER MORE. Keen to hear your views!

http://northern-doctors.org/# mexican online pharmacies prescription drugs

mexican online pharmacies prescription drugs: Mexico pharmacy that ship to usa – buying from online mexican pharmacy

https://northern-doctors.org/# buying prescription drugs in mexico

reputable mexican pharmacies online: mexican pharmacy northern doctors – mexican border pharmacies shipping to usa

https://northern-doctors.org/# mexican pharmacy

buying from online mexican pharmacy: Mexico pharmacy that ship to usa – buying prescription drugs in mexico online

mexican pharmaceuticals online: mexican pharmacy online – mexican pharmacy

https://northern-doctors.org/# medication from mexico pharmacy

mexican pharmaceuticals online: Mexico pharmacy that ship to usa – purple pharmacy mexico price list

mexican mail order pharmacies [url=https://northern-doctors.org/#]mexican northern doctors[/url] purple pharmacy mexico price list

https://northern-doctors.org/# mexican drugstore online

https://northern-doctors.org/# pharmacies in mexico that ship to usa

mexican pharmaceuticals online: Mexico pharmacy that ship to usa – buying prescription drugs in mexico

reputable mexican pharmacies online [url=http://northern-doctors.org/#]best online pharmacies in mexico[/url] mexican border pharmacies shipping to usa

http://northern-doctors.org/# mexican drugstore online

mexican online pharmacies prescription drugs [url=http://cmqpharma.com/#]cmqpharma.com[/url] mexican border pharmacies shipping to usa

buying prescription drugs in mexico [url=http://cmqpharma.com/#]buying from online mexican pharmacy[/url] buying from online mexican pharmacy

mexico pharmacies prescription drugs [url=https://cmqpharma.com/#]cmqpharma.com[/url] medicine in mexico pharmacies

In recent times, Africa has come about as a lively hub for audio and celebrity traditions, gaining international recognition and influencing global trends. African music, using its rich tapestry of genres such as Afrobeats, Amapiano, and highlife, offers captivated audiences throughout the world. Major artists like Burna Boy, Wizkid, and Tiwa Savage have not only dominated the charts in Africa but have also made considerable inroads into the global music landscape. Their collaborations using international stars plus performances at major music festivals possess highlighted the continent’s musical prowess. The rise of electronic digital platforms and interpersonal media has even more amplified the reach of African tunes, allowing artists to connect with followers across the earth and share their unique sounds and testimonies – https://afriquestories.com/la-musique-contemporaine-a-la-reunion/.

In addition to be able to its musical talent, Africa’s celebrity culture is flourishing, using entertainers, influencers, in addition to public figures instructing large followings. Superstars such as Lupita Nyong’o, Trevor Noah, and Charlize Theron, who have root base in Africa, are usually making waves internationally in film, television set, and fashion. These kinds of figures not just bring attention to their particular work but in addition shed light on important social issues and cultural heritage. Their good results stories inspire a new new generation of Africans to pursue careers in the entertainment industry, fostering a feeling of pride in addition to ambition across the continent.

Moreover, African celebrities are more and more using their programs to advocate intended for change and provide to their residential areas. From Burna Boy’s activism around cultural justice issues to Tiwa Savage’s attempts in promoting education for girls, these open figures are using their influence with regard to positive impact. They can be involved in numerous philanthropic activities, helping causes such because healthcare, education, plus environmental sustainability. This particular trend highlights the particular evolving role of celebrities in The african continent, who are not simply entertainers but likewise key players inside driving social change and development.

Total, the landscape of music and movie star culture in Africa is dynamic and ever-evolving. The continent’s rich cultural range and creative talent continue to garner intercontinental acclaim, positioning The african continent as being a major power inside the global entertainment industry. As Black artists and celebrities continue to break barriers and achieve new heights, they pave how for some sort of more inclusive and diverse representation within global media. For those interested within staying updated in the latest trends and news throughout this vibrant scene, numerous platforms in addition to publications offer in-depth coverage of Africa’s music and superstar happenings, celebrating typically the continent’s ongoing efforts to the planet stage.

pharmacies in mexico that ship to usa [url=http://cmqpharma.com/#]medicine in mexico pharmacies[/url] mexico pharmacy

mexican pharmaceuticals online: cmqpharma.com – mexican pharmaceuticals online

mexico drug stores pharmacies [url=http://cmqpharma.com/#]cmq mexican pharmacy online[/url] mexico pharmacies prescription drugs

mexican rx online [url=https://cmqpharma.com/#]cmq pharma mexican pharmacy[/url] п»їbest mexican online pharmacies

buying from online mexican pharmacy [url=http://cmqpharma.com/#]cmq pharma[/url] mexico pharmacies prescription drugs

mexican mail order pharmacies

https://cmqpharma.online/# mexican pharmaceuticals online

buying prescription drugs in mexico

buying prescription drugs in mexico [url=http://cmqpharma.com/#]cmq mexican pharmacy online[/url] mexican border pharmacies shipping to usa

mexican pharmaceuticals online [url=http://cmqpharma.com/#]mexico pharmacy[/url] reputable mexican pharmacies online

Профессиональные seo https://seo-optimizaciya-kazan.ru услуги для максимизации онлайн-видимости вашего бизнеса. Наши эксперты проведут глубокий анализ сайта, оптимизируют контент и структуру, улучшат технические аспекты и разработают индивидуальные стратегии продвижения.

Top sports news https://idman-azerbaycan.com.az photos and blogs from experts and famous athletes, as well as statistics and information about matches of leading championships.

Latest news and details about the NBA in Azerbaijan https://nba.com.az. Hot events, player transfers and the most interesting events. Explore the world of the NBA with us.

The latest top football news https://futbol.com.az today. Interviews with football players, online broadcasts and match results, analytics and football forecasts, photos and videos.

Discover the fascinating world of online games with GameHub Azerbaijan https://online-game.com.az. Get the latest news, reviews and tips for your favorite games. Join our gaming community today!

Каталог рейтингов хостингов https://pro-hosting.tech на любой вкус и под любые, даже самые сложные, задачи.

https://santekhnik-moskva.blogspot.com — вызов сантехника на дом в Москве и Московской области в удобное для вас время.

Play PUBG Mobile https://pubg-mobile.com.az an exciting world of high-quality mobile battle royale. Unique maps, strategies and intense combat await you in this exciting mobile version of the popular game.

The Dota 2 website https://dota2.com.az Azerbaijan provides the most detailed information about the latest game updates, tournaments and upcoming events. We have all the winning tactics, secrets and important guides.

Check out the latest news, guides and in-depth reviews of the available options for playing Minecraft Az https://minecraft.com.az. Find the latest information about Minecraft Download, Pocket Edition and Bedrock Edition.

The most popular sports site https://sports.com.az of Azerbaijan, where the latest sports news, forecasts and analysis are collected.

Latest news and analytics of the Premier League https://premier-league.com.az. Detailed descriptions of matches, team statistics and the most interesting football events. EPL Azerbaijan is the best place for football fans.

Хотите сделать в квартире ремонт? Тогда советуем вам посетить сайт https://stroyka-gid.ru, где вы найдете всю необходимую информацию по строительству и ремонту.

Latest news about games for Android https://android-games.com.az, reviews and daily updates. Read now and get the latest information on the most exciting games

1xbet https://1xbet.best-casino-ar.com with withdrawal without commission. Register online in a few clicks. A large selection of slot machines in mobile applications and convenient transfers in just a few minutes.

Pin-up Casino https://pin-up.admsov.ru/ is an online casino licensed and regulated by the government of Curacao . Founded in 2016, it is home to some of the industry’s leading providers, including NetEnt, Microgaming, Play’n GO and others. This means that you will be spoiled for choice when it comes to choosing a game.

Pin Up official https://pin-up.adb-auto.ru website. Login to your personal account and register through the Pin Up mirror. Slot machines for real money at Pinup online casino.

Pin Up Casino https://pin-up.noko39.ru Registration and Login to the Official Pin Up Website. thousands of slot machines, online tables and other branded entertainment from Pin Up casino. Come play and get big bonuses from the Pinup brand today

Pin Up online casino https://pin-up.webrabota77.ru/ is the official website of a popular gambling establishment for players from the CIS countries. The site features thousands of slot machines, online tables and other branded entertainment from Pin Up casino.

Реальные анкеты проституток https://prostitutki-213.ru Москвы с проверенными фото – от элитных путан до дешевых шлюх. Каталог всех индивидуалок на каждой станции метро с реальными фотографиями без ретуши и с отзывами реальных клиентов.

Смотрите онлайн сериал Отчаянные домохозяйки https://domohozyayki-serial.ru в хорошем качестве HD 720 бесплатно, рейтинг сериала: 8.058, режиссер сериала: Дэвид Гроссман, Ларри Шоу, Дэвид Уоррен.

Buy TikTok followers https://tiktok-followers-buy.com to get popular and viral with your content. All packages are real and cheap — instant delivery within minutes. HQ followers for your TikTok. 100% real users. The lowest price for TikTok followers on the market

Pin Up Casino https://pin-up.sibelshield.ru official online casino website for players from the CIS countries. Login and registration to the Pin Up casino website is open to new users with bonuses and promotional free spins.

Изготовление памятников и надгробий https://uralmegalit.ru по низким ценам. Собственное производство. Высокое качество, широкий ассортимент, скидки, установка.

Pin Up Casino https://pin-up.ergojournal.ru приглашает игроков зарегистрироваться на официальном сайте и начать играть на деньги в лучшие игровые автоматы, а на зеркалах онлайн казино Пин Ап можно найти аналогичную витрину слотов

Pin-up casino https://pin-up.jes-design.ru популярное онлайн-казино и ставки на спорт. Официальный сайт казино для доступа к играм и другим функциям казино для игры на деньги.

Pin Up https://pin-up.fotoevolution.ru казино, которое радует гемблеров в России на протяжении нескольких лет. Узнайте, что оно подготовило посетителям. Описание, бонусы, отзывы о легендарном проекте. Регистрация и вход.

Открой мир карточных игр в Pin-Up https://pin-up.porsamedlab.ru казино Блэкджек, Баккара, Хило и другие карточные развлечения. Регистрируйтесь и играйте онлайн!

Официальный сайт Pin Up казино https://pin-up.nasledie-smolensk.ru предлагает широкий выбор игр и щедрые бонусы для игроков. Уникальные бонусные предложения, онлайн регистрация.

Pinup казино https://pin-up.vcabinet.kz это не просто сайт, а целый мир азартных развлечений, где каждый может найти что-то свое. От традиционных игровых автоматов до прогнозов на самые популярные спортивные события.

Latest Diablo news https://diablo.com.az game descriptions and guides. Diablo.az is the largest Diablo portal in the Azerbaijani language.

Latest World of Warcraft (WOW) tournament news https://wow.com.az, strategies and game analysis. The most detailed gaming portal in Azerbaijani language

Azerbaijan NFL https://nfl.com.az News, analysis and topics about the latest experience, victories and records. A portal where the most beautiful NFL games in the world are generally studied.

Discover exciting virtual football in Fortnite https://fortnite.com.az. Your central hub for the latest news, expert strategies and interesting e-sports reports. Collecting points with us!

The latest analysis, tournament reviews and the most interesting features of the Spider-Man game https://spider-man.com.az series in Azerbaijani.

Read the latest Counter-Strike 2 news https://counter-strike.net.az, watch the most successful tournaments and become the best in the world of the game on the CS2 Azerbaijan website.

Mesut Ozil https://mesut-ozil.com.az latest news, statistics, photos and much more. Get the latest news and information about one of the best football players Mesut Ozil.

Latest news, statistics, photos and much more about Pele https://pele.com.az. Get the latest news and information about football legend Pele.

Explore the extraordinary journey of Kilian Mbappe https://kilian-mbappe.com.az, from his humble beginnings to global stardom. Delve into his early years, meteoric rise through the ranks, and impact on and off the football field.

Latest boxing news https://boks.com.az, Resul Abbasov’s achievements, Tyson Fury’s fights and much more. All in Ambassador Boxing.

Sergio Ramos Garcia https://sergio-ramos.com.az Spanish footballer, defender. Former Spanish national team player. He played for 16 seasons as a central defender for Real Madrid, where he captained for six seasons.

Gianluigi Buffon https://buffon.com.az Italian football player, goalkeeper. Considered one of the best goalkeepers of all time. He holds the record for the number of games in the Italian Championship, as well as the number of minutes in this tournament without conceding a goal.

Paulo Bruno Ezequiel Dybala https://dybala.com.az Argentine footballer, striker for the Italian club Roma and the Argentina national team. World champion 2022.

Paul Labille Pogba https://pogba.com.az French footballer, central midfielder of the Italian club Juventus. Currently suspended for doping and unable to play. World champion 2018.

Канал для того, чтобы знания и опыт, могли помочь любому человеку сделать ремонт https://tvin270584.livejournal.com в своем жилище, любой сложности!

Kevin De Bruyne https://kevin-de-bruyne.liverpool-fr.com Belgian footballer, born 28 June 1991 years in Ghent. He has had a brilliant club career and also plays for the Belgium national team. De Bruyne is known for his spectacular goals and brilliant assists.

Mohamed Salah Hamed Mehrez Ghali https://mohamed-salah.liverpool-fr.com Footballeur egyptien, attaquant du club anglais de Liverpool et l’equipe nationale egyptienne. Considere comme l’un des meilleurs joueurs du monde.

The young talent who conquered Paris Saint-Germain: how Xavi Simons became https://xavi-simons.psg-fr.com leader of a superclub in record time.

Paul Labille Pogba https://paul-pogba.psg-fr.com Footballeur francais, milieu de terrain central du club italien de la Juventus. Champion du monde 2018. Actuellement suspendu pour dopage et incapable de jouer.

Kylian Mbappe https://kylian-mbappe.psg-fr.com Footballeur, attaquant francais. Il joue pour le PSG et l’equipe de France. Ne le 20 decembre 1998 a Paris. Mbappe est francais de nationalite. La taille de l’athlete est de 178 cm.

Kevin De Bruyne https://liverpool.kevin-de-bruyne-fr.com Belgian footballer, born 28 June 1991 years in Ghent. He has had a brilliant club career and also plays for the Belgium national team. De Bruyne is known for his spectacular goals and brilliant assists.

Paul Pogba https://psg.paul-pogba-fr.com is a world-famous football player who plays as a central midfielder. The player’s career had its share of ups and downs, but he was always distinguished by his perseverance and desire to win.

Kylian Mbappe https://psg.kylian-mbappe-fr.com Footballeur, attaquant francais. L’attaquant de l’equipe de France Kylian Mbappe a longtemps refuse de signer un nouveau contrat avec le PSG, l’accord etant en vigueur jusqu’a l’ete 2022.

Изготовление, сборка и ремонт мебели https://shkafy-na-zakaz.blogspot.com для Вас, от эконом до премиум класса.

Thibaut Nicolas Marc Courtois https://thibaut-courtois.real-madrid-ar.com Footballeur belge, gardien de but du Club espagnol “Real Madrid”. Lors de la saison 2010/11, il a ete reconnu comme le meilleur gardien de la Pro League belge, ainsi que comme joueur de l’annee pour Genk. Trois fois vainqueur du Trophee Ricardo Zamora, decerne chaque annee au meilleur gardien espagnol

Forward Rodrigo https://rodrygo.real-madrid-ar.com is now rightfully considered a rising star of Real Madrid. The talented Santos graduate is compared to Neymar and Cristiano Ronaldo, but the young talent does not consider himself a star.

Jude Victor William Bellingham https://jude-bellingham.real-madrid-ar.com English footballer, midfielder of the Spanish club Real Madrid and the England national team. In April 2024, he won the Breakthrough of the Year award from the Laureus World Sports Awards.

Saud Abdullah Abdulhamid https://saud-abdulhamid.real-madrid-ar.com Saudi footballer, defender of the Al -Hilal” and the Saudi Arabian national team. Asian champion in the age category up to 19 years. Abdulhamid is a graduate of the Al-Ittihad club. On December 14, 2018, he made his debut in the Saudi Pro League in a match against Al Bateen

Khvicha Kvaratskhelia https://khvicha-kvaratskhelia.real-madrid-ar.com midfielder of the Georgian national football team and the Italian club “Napoli”. Became champion of Italy and best player in Serie A in the 2022/23 season. Kvaratskhelia is a graduate of Dynamo Tbilisi and played for the Rustavi team.

Vinicius Junior https://vinisius-junior.com.az player news, fresh current and latest events for today about the player of the 2024 season

Latest news and information about Marcelo https://marcelo.com.az on this site! Find Marcelo’s biography, career, playing stats and more. Find out the latest information about football master Marcelo with us!

Khabib Abdulmanapovich Nurmagomedov https://khabib-nurmagomedov.com.az Russian mixed martial arts fighter who performed under the auspices of the UFC. Former UFC lightweight champion.

Welcome to our official site! Get to know the history, players and latest news of Inter Miami Football Club https://inter-miami.com.az. Discover with us the successes and great performances of America’s newest and most exciting soccer club.

Conor Anthony McGregor https://conor-mcgregor.com.az Irish mixed martial arts fighter who also performed in professional boxing. He performs under the auspices of the UFC in the lightweight weight category. Former UFC lightweight and featherweight champion.

Оперативный вывод из запоя https://www.liveinternet.ru/users/laralim/post505923855/ на дому. Срочный выезд частного опытного нарколога круглосуточно. При необходимости больного госпитализируют в стационар.

Видеопродакшн студия https://humanvideo.ru полного цикла. Современное оборудование продакшн-компании позволяет снимать видеоролики, фильмы и клипы высокого качества. Создание эффективных видеороликов для рекламы, мероприятий, видеоролики для бизнеса.

Заказать вывоз мусора https://musorovozzz.ru в Москве и Московской области, недорого и в любое время суток в мешках или контейнерами 8 м?, 20 м?, 27 м?, 38 м?, собственный автопарк. Заключаем договора на вывоз мусора.

Реальные анкеты https://prostitutki-vyzvat-moskva.ru Москвы с проверенными фото – от элитных путан до дешевых шлюх. Каталог всех индивидуалок на каждой станции метро с реальными фотографиями без ретуши и с отзывами реальных клиентов.

Совсем недавно открылся новый интернет портал BlackSprut (Блекспрут) https://bs2cite.cc в даркнете, который предлагает купить нелегальные товары и заказать запрещенные услуги. Самая крупнейшая площадка СНГ. Любимые шопы и отзывчивая поддержка.

Welcome to the site dedicated to Michael Jordan https://michael-jordan.com.az, a basketball legend and symbol of world sports culture. Here you will find highlights, career, family and news about one of the greatest athletes of all time.

Gucci купить http://thebestluxurystores.ru по низкой цене в интернет-магазине брендовой одежды. Одежда и обувь бренда Gucci c доставкой.

Muhammad Ali https://muhammad-ali.com.az American professional boxer who competed in the heavy weight category; one of the most famous boxers in the history of world boxing.

Монтаж систем отопления https://fectum.pro, водоснабжения, вентиляции, канализации, очистки воды, пылеудаления, снеготаяния, гелиосистем в Краснодаре под ключ.