Straw Wattles – Applications & Installation

Straw wattles are cylinders of compressed straw wrapped in synthetic or natural netting. They are designed to filter sediment runoff and reduce hydraulic forces.

Applications

Straw wattles are used in many applications, like preventing slope erosion and the spread of sediment on construction sites. They can also control stormwater runoff, protect storm drains, and promote stabilization of shorelines and stream banks.

Soil Stabilization

Vegetation is one of the greatest stabilizers of loose soil for slopes. Straw wattles store moisture for vegetation and incorporate themselves into the soil over time. The topsoil, native seeds, and other organic material come together to promote an ideal environment for germination and plant growth. Vegetation grows through the straw wattle, locking soil in place for long-lasting stabilization.

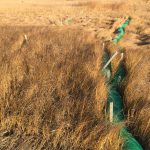

Slope Stabilization

In addition to providing soil stabilization with vegetation growth, straw wattles can also be used to control erosion that occurs on steep slopes. They are installed horizontally at even intervals down a slope, locking soil and organic matter in place. This reduces the hydraulic forces of a slope and creates a more stable environment.

Runoff Control

Straw wattles are commonly used to control and divert stormwater runoff. For example, they can be installed near roadways to divert stormwater toward treatment areas, away from routes that will erode the roadway or cause flooding.

Storm Drains

Straw wattles are an effective method of preventing sediment and contaminants from entering storm drains. Wrapping them around storm drain inlets on a construction site helps protect the environment.

Check Dams

Straw wattles can also be used as check dams on drainage ditches, channels, and swales to prevent sheet erosion and gully development. Installing them perpendicular to water flow will reduce water velocity and prevent the undermining of channel lining materials.

Downslope Installation

The first step in the downslope installation is determining the spacing of the straw wattles. Different slopes and soil conditions require different spacing between wattles. 1:1 slopes generally require wattles to be installed in 10-foot intervals. 2:1 slopes can be 20 feet apart, 3:1 slopes can be 30 feet apart, and so on. Soft, loamy soil requires the wattles to be installed closer together, and hard, rocky soils can have the wattles spaced farther apart.

The next step is trenching. Use a shovel to dig a trench along the slope, placing excavated soil on the uphill. Soft and loamy soils require deeper trenches, around 3 to 5 inches. Hard and rocky soil only requires a 2 to 3-inch trench.

Place the straw wattles into the trench and make sure they are snug. You should not be able to see daylight from underneath the wattle. Pack soil against the wattle on the uphill side and begin staking them down. Wattles must be staked on each end and four feet on center. Drive stakes through the very middle of the wattle and leave 2-3 inches of stake above the wattle. Driving the stakes too low could result in the wattle getting pulled off the stakes. The stakes must be driven perpendicular to the slope.

Purchase Straw Wattles

At IWT Cargo-Guard, we offer a variety of sediment control and slope stabilization products that provide the best management practices for your work site. Our products are made with high-strength, high-quality materials that withstand the stresses associated with sediment runoff near waterways.

From straw wattles to coir logs and silt fences, we’ll equip you with the right sediment control products for your project. IWT Cargo Guard’s mission is to provide the most cost-effective products for your project. By quickly analyzing the products and services required for the project, we become an extension of your estimating department. Contact us today to get started,